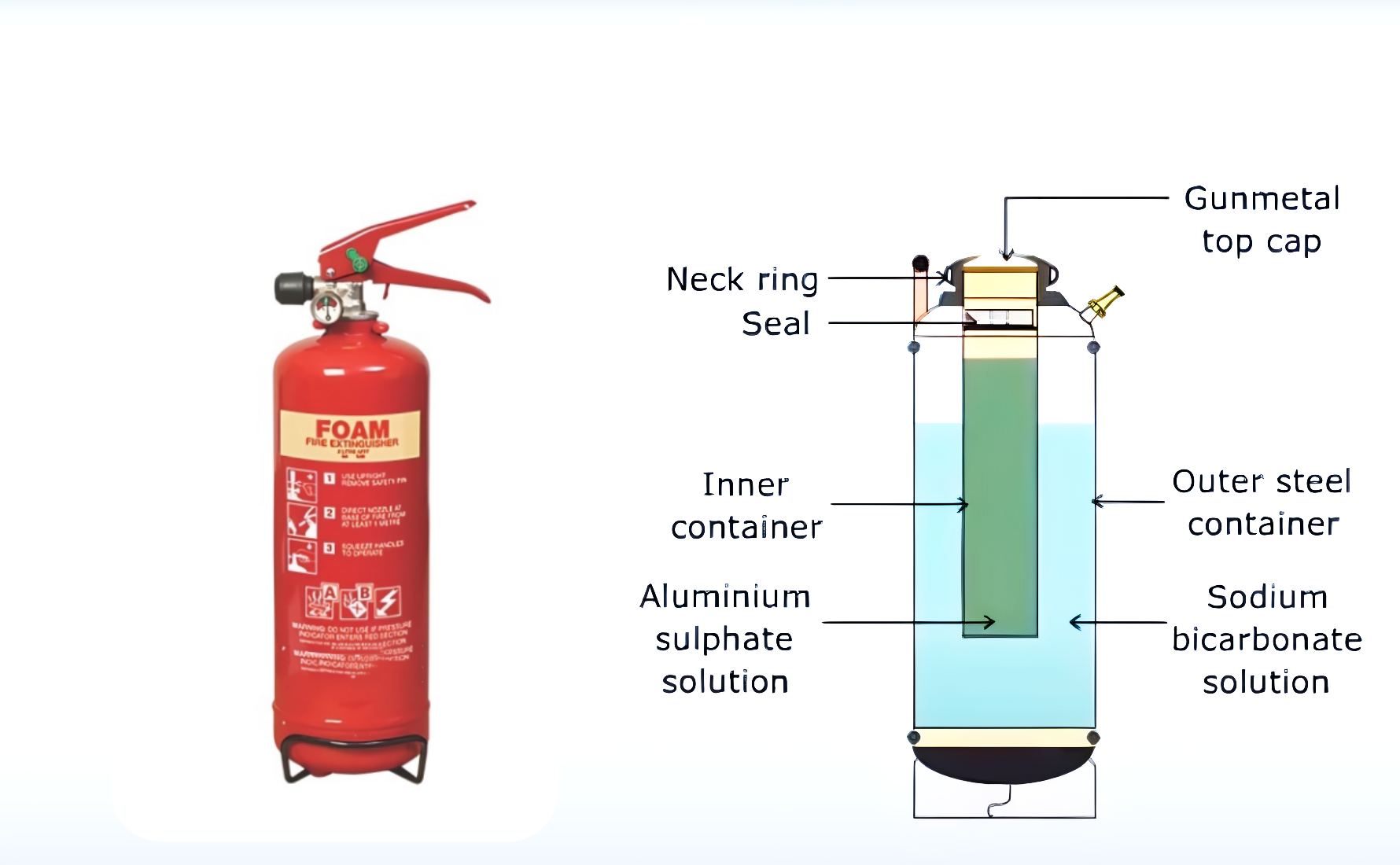

Foam fire extinguisher is mainly composed of a cylinder, a bottle, a cylinder cover, a lifting ring and a nozzle, and can only be placed upright. The cylinder contains an alkaline mixed solution of sodium bicarbonate and a foaming agent, and the bottle contains an acidic aqueous solution of aluminum sulfate. The bottle is covered with a bottle cap to prevent the acidic solution from evaporating or mixing with the alkaline solution due to splashing due to vibration.

What is a Foam Fire Extinguisher Used for?

1) Suitable for extinguishing general fires, such as fires of oil products, grease, etc. that cannot be extinguished with water.

2) Cannot extinguish fires of water-soluble combustible and flammable liquids, such as alcohol, ester, ether, ketone, etc.

3) Foam extinguishers cannot be used to extinguish fires of live electrical equipment.

How to Use?

Lift the fire extinguisher steadily to about 10m away from the fire point, turn it upside down, hold the lifting ring with one hand and the bottom ring of the cylinder with the other hand, aim the nozzle at the burning object. The acidic and alkaline solutions will react chemically after mixing to produce carbon dioxide gas foam, which will be sprayed out from the nozzle and cover the burning object, isolating the combustible material from the air and lowering the temperature to achieve the purpose of extinguishing the fire.

Working Principle of Foam Fire Extinguishers

Operate by forming a thick, stable foam blanket over the burning material. This foam layer serves three main purposes:

-

Oxygen exclusion: The foam blanket separates the fuel surface from the surrounding air, cutting off the oxygen supply necessary for combustion.

-

Cooling effect: The water content in the foam cools the burning fuel and surrounding surfaces, reducing the temperature below the ignition point.

-

Vapor suppression: The foam suppresses the release of flammable vapors, further preventing re-ignition.

The extinguishing agents used in foam fire extinguishers typically include:

-

Aqueous Film Forming Foam (AFFF): The most common type, forming a thin aqueous film on the fuel surface in addition to the foam blanket.

-

Protein foam: Derived from natural protein materials, offering excellent burn-back resistance.

-

Synthetic foam: Based on synthetic surfactants, providing better stability and versatility in various conditions.

Types of Foam Fire Extinguishers

Portable fire extinguisher foam: Handheld units suitable for small to medium-sized fires, typically found in commercial and industrial settings.

Wheeled fire extinguishers foam: Larger, mobile units designed for bigger fire risks such as warehouses, fuel depots, and industrial plants.

Main Application Fields

It is extensively used in industries and facilities where flammable liquids pose a significant risk:

Petrochemical plants and refineries

Oil storage facilities and gas stations

Airports and aircraft hangars

Shipyards and marine vessels

Manufacturing plants with flammable substances

Their ability to rapidly suppress large-scale liquid fires makes them indispensable in these environments.

Advantages and Disadvantages

Advantages

Quick fire suppression: Foam spreads rapidly over the fuel surface, extinguishing flames and preventing reignition.

Cooling capabilities: The water content helps cool down the fuel and nearby surfaces.

Coverage of large areas: Foam can effectively blanket large spill fires.

Disadvantages

Not safe for electrical fires: Due to water content, foam conducts electricity.

Environmental concerns: Traditional foams, especially fluorinated foams like PFAS-based AFFF, can persist in the environment and have been linked to health issues.

Maintenance complexity: Foam systems require regular inspection and maintenance to ensure performance.

Maintenance and Inspection

Proper maintenance is essential to ensure the reliability of foam fire extinguishers. Key steps include:

Regularly checking pressure gauges, nozzles, seals, and valves.

Monitoring the condition and concentration of foam agents; some agents have limited shelf life.

Ensuring proper storage temperatures to prevent agent degradation.

Conducting periodic operator training and emergency response drills to maintain readiness.