DCP dry powder fire extinguisher is highly versatile safety devices suitable for both residential and commercial use. Capable of combating various fire types—including solid materials, flammable liquids, gases, and electrical fires—they are a fundamental part of any fire protection strategy. However, selecting the correct type and size is critical for optimal safety.

Standard dry powder extinguishers work by releasing a chemical powder that forms a barrier, cutting off the fire’s oxygen supply and suppressing flames. Their multi-risk capabilities make them a popular choice.

Types of DCP Dry powder Fire Extinguishers & Their Applications

Since certain dry chemical fire extinguisher is designed for specific fire hazards, it’s essential to choose the right one for your environment.

The ABC powder extinguisher is the most widely used variant, offering protection against:

Class A fires (combustible solids like wood or paper)

Class B fires (flammable liquids such as gasoline or oil)

Class C fires (gas fires, including propane or methane)

ABC extinguishers are also safe for electrical fires, as the powder does not conduct electricity. This versatility makes them the ideal fire protection solution for both residential and commercial settings. While it offers broad protection against Class A, B, C, and electrical fires, they have specific limitations:

Not effective for kitchen fires involving cooking oils/fats (require Class K extinguishers)

Unsuitable for combustible metal fires (e.g., magnesium, sodium – require Class D extinguishers)

Selecting the Proper DCP Dry Powder Extinguisher Size

Beyond choosing the right type of dcp fire extinguisher, selecting the correct size is equally important. For small spaces like vans or homes, the 2kg model is a popular choice—its lighter weight makes it easier to handle and operate in emergencies.

For larger or higher-risk environments, 4kg, 6kg, and 9kg models are available. The 9kg extinguisher is particularly suited for industrial or outdoor settings, where rapid suppression of larger fires may be necessary to prevent escalation or ensure safe evacuation.

Large capacity trolley fire extinguisher: industrial and storage environments, energy and power facilities, public places and transportation hubs, tank farms/power stations/factories, suitable for medium and large initial fires

Quality Assurance & Customization Services

We supply premium ABC fire extinguishers that meet the highest industry standards, including ISO certification and EN3 compliance, ensuring safety, reliability, and performance. Additionally, we assist with import certification to help your products meet local regulatory requirements in different markets.

Customization Options

To align with your brand and operational needs, we offer flexible customization for:

Dry Powder Composition,Color – Tailored formulations for specific fire risks (ABC, BC, or specialized powders).

Logo Branding – Custom shell colors, logo printing, and labeling to enhance brand visibility.

Packaging – Branded packaging solutions for retail, industrial, or bulk shipments.

Craft for DCP dry powder fire extinguishers

ABC fire extinguishers are not only known for their firefighting capabilities but also for their robust physical design. There are three processes for making the cylinder body: five-lobe recessed base, stretching, and welding. The five-lobe recessed base bottom usually comes with a base, Skirt Ring or Rounded Base. Five-lobe recessed base is often used in DCP extinguishers.

They typically feature a durable drawn-steel cylinder, which is essential for withstanding the high pressures required for storing firefighting agents. The strong construction ensures that the extinguisher can handle the rigors of various environments, from the heat of industrial settings to the cold of outdoor storage.

Cylinder Interior Processing Techniques:

- Rotational Molding

– Provides superior corrosion resistance

– Prevents water permeation

– Ideal for harsh environments (e.g., marine/chemical applications)

- Powder Coating more cost-effective solution

– Maintains good corrosion protection

– Common choice for standard industrial/commercial use

Key Advantages & Limitations

Advantage

Multi-Class Fire Protection

Effectively combats Class A (combustibles like wood/paper), Class B (flammable liquids), and Class C (electrical equipment) fires, providing comprehensive coverage for diverse fire risks.

Electrical Safety

The non-conductive properties ensure safe operation on live electrical equipment without shock hazards.

Immediate Fire Control

Rapid flame suppression through oxygen displacement creates instant fire containment, significantly reducing fire spread potential.

Liquid Fire Capability

Demonstrates particular effectiveness against flowing fuel fires when combined with foam application techniques.

Thermal Protection

Discharge forms a protective heat barrier, shielding both structures and personnel from radiant heat exposure.

Environmental Adaptability

Maintains operational reliability across extreme temperatures (-20°C to +60°C), suitable for diverse climate conditions.

Space-Efficient Design

Available in multiple compact configurations (1-12kg) for flexible placement in various facility layouts.

Intuitive Operation

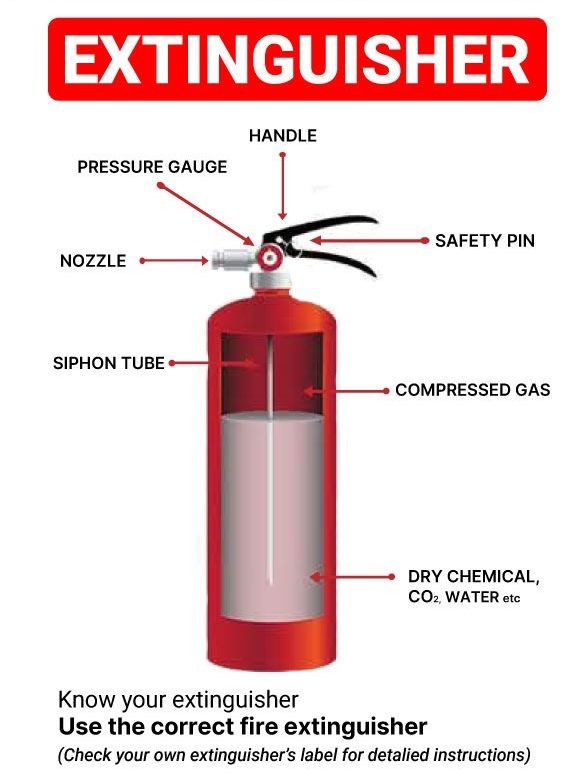

Features clear pictographic instructions and simple pull-pin mechanism for emergency readiness by all user levels.

Important Limitations to Consider:

While dry powder extinguishers offer excellent versatility for Class A, B, C, and electrical fires, they have specific restrictions:

Not suitable for:

- Class F fires (kitchen oils/fat fires – requires wet chemical extinguishers)

- Class D fires (combustible metals like magnesium or sodium – requires specialized metal fire extinguishers)

Residue concerns:

The powder leaves a corrosive residue that may damage:

- ✓ Sensitive electronics

- ✓ Precision machinery

- ✓ Unprotected surfaces

Professional Recommendation:

Always:

- Match extinguisher type to your specific fire risks

- Consider CO₂or clean agent extinguishers for electronics areas

- Plan post-discharge cleanup procedures